INTECH Cable Support System

INTEC Cable Support System

INTECH FRP Cable Support System is an advanced composite solution designed to meet the rigorous demands of Oil & Gas, utilities and offshore applications. Made from high-performance Fiber Reinforced Polymer (FRP), it offers unparalleled durability, safety, and resistance to harsh environmental conditions.

Our products are manufactured using advanced resin technologies, including vinyl ester, isophthalic polyester, and phenolic resins, which provide exceptional protection against corrosion, UV exposure, and chemical degradation. These properties make it an ideal choice for applications in industries such as oil and gas, petrochemical, marine, and power generation.

INTECH FRP Cable Support System is distinguished by its essential features, including anti-static capability that effectively dissipates static electricity, significantly minimizing the risk of spark generation and enhancing safety in flammable and explosive environments. Fire-retardant properties and low-smoke emission options can be tailored to meet the specific needs of various applications, ranging from offshore and onshore settings to commercial installations, enclosed spaces, and even underground tunnels.

Additionally, the system boasts high mechanical strength, offering superior load-bearing capacity while maintaining a lightweight design that simplifies handling and installation.

All our products are tested & complies to international standards such as NEMA , IEC and UL 568. All of which are independently certified by ABS product type approval.

Benefits of Pultrusion FRP Products

Corrosion Resistant

No rusting, peeling or flaking even under the most aggressive conditions in any part of the world.

High Impact Resistant & Elastic

Choose a pre-built header or create a custom layout that perfectly suits your needs.

Lightweight and Durable

Allows easy handling and cutting and reduce size of platform structure.

Superior UV Protection

Integral UV protection system gives long-term shield against the damaging effects of UV rays.

Cost Effective

Extremely long life and completely maintenance-free

Non-Conductive & Non-Interfering

Doesn't conduct heat like metal and remains unaffected by heat expansion.

High Strength and Stiffness

High glass content and continuous reinforcement, pultruded FRP products that give extremely high strength and stiffness

Fire Retardant

Complies to ASTM-E84 and BS 476 standards.

High Impact Resistant & Elastic

Returns to original position without any permanent deflection or distortion within allowable loads.

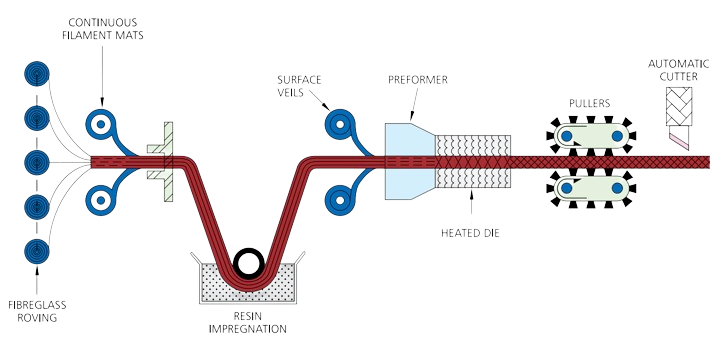

What is Pultrusion Process

Pultrusion is a continuous moulding process fabricating products of uniformsection such as I Beams, Channels, flat Bars, Rods,Hollow Sections, etc. Msing glass fibre, resin, fillet peroxide and a release agent. The glass reinforcement is drawn into a resin impregnation zone where the Mass substrate is thoroughly impregnated with the main mixture. The wet fibrous materiss will be pulled through a preformer into a heated die. The shape of the end product is determined by the configuration of the die and the resin is then polymerised. This continuous and uniform method ensures consistency throughout the entire product length, therefore eliminating the possibility of weak spots.

FRP Pultrusion Process

The latest design trends meet hand-crafted templates in Hub Collection. Use pre-built sections to speed up your design process.

Applications

How to Choose the Right Resin

1 1

STEP 1

Understand the Environment

Assess exposure to chemicals, UV light, moisture, or high temperatures.

2 2

STEP 2

Identify Safety Requirements

Determine the need for fire resistance, low smoke emissions, or anti-static properties.

3 3

STEP 3

Consult

Our Experts

If unsure, our team can guide you in selecting the resin that best meets your project’s demands.

Resin Selection Guide for INTECH FRP Products

Choosing the right resin type is critical for ensuring the performance, durability, and safety of your INTECH FRP cable support systems. Below is a simplified guide to help clients select the most suitable resin based on application requirements and environmental conditions.

Isophathalic (ISO) Resin is the most commonly used resin that provides good corrosion and ultraviolet light resistance for various application.

Best For:

- General industrial applications

Key Features:

- Excellent resistance to moderate to high corrosion.

- Suitable for environments with intermittent chemical exposure.

- Cost-effective for standard applications.

Typical Use Cases:

- Power plants, commercial buildings, and indoor applications.

VE resin is formulated for reliable performance in the harshest chemical environment, providing outstanding resistance towards wide range of highly corrosive applications ranging from causting to strong acidic.

Best For:

- Harsh chemical and corrosive environments

Key Features:

- Superior chemical resistance to acids, alkalis, and solvents.

- Excellent thermal stability and impact strength.

- Ideal for environments requiring higher durability.

Typical Use Cases:

- Offshore platforms, petrochemical plants, and wastewater treatment facilities.

Best For:

- Explosive and flammable environments. High hydrocarbon exposure areas.

Key Features:

- Effectively dissipates static electricity to prevent spark generation.

- Enhances safety in hazardous zones.

Typical Use Cases:

- Oil and gas facilities, mining operations, and chemical storage areas.

Best For:

- Ideal for areas with strict fire safety regulations.

Key Features:

- Produces minimal smoke in case of fire, ensuring enhanced visibility and safer evacuation in enclosed spaces.

- Fire Retardancy: Meets or exceeds the requirements of ASTM E84 Class A, with a smoke smission of below 450

- Durability: Retains structural integrity under high temperatures while resisting chemical exposure.

Typical Use Cases:

- Underground Tunnels: Reduces smoke hazard in confined spaces.

- Mass Transit Systems: Enhances passenger safety in subways, railways, and bus depots.

- Commercial and Industrial Enclosures

Download Product Catalogue

Explore our comprehensive product offerings! Download our latest catalogue now to discover the full range of solutions tailored to meet your needs