Gratings

Gratings

FRP (Fiberglass Reinforced Plastic) is produced from a combination of fiberglass reinforcements and thermosetting resins. Since its introduction, this special millennium product has gained wide acceptance for its superior benefits and is presently used all over the world.

Benefits of INTECH FRP Pultruded and Molded Grating

Corrosion Resistance

No rusting, peeling or flaking, even under the most aggressive conditions in any part of the world.

Superior Weatherability

INTECH’s integral UV protection system gives long term protection against UV attack.

Lightweight and Durable

Lightweight of FRP ease handling and cutting, reduce size of platform structure.

Non-Conductive & Non-Interfering

Complies to international electrical safety specification and transparent to radio waves and is nonmagnetic.

Cost Effective

Extremely long life compared to metal and others plastic, “with no maintenance required.”

Low Thermal Conductivity & Expansion Rate

Will not transfer heat, and no problem of expansion under heat.

High Strength and Stiffness

High glass content and continuous reinforcement, pultruded FRP products give extremely high strength and stiffness compared to other engineering plastic.

Fire Retardant

Fire retardant quality is available with compliance to ASTM-E84 and BS 476 standards.

High Impact Resistance & Elastic

Returns to original position without any permanent deflection or distortion with allowable loads.

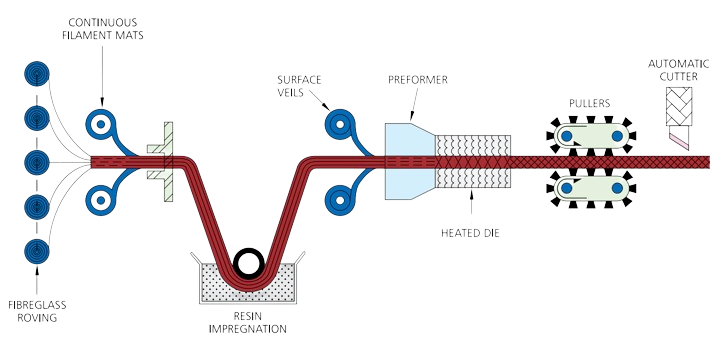

What is Pultrusion Process

Pultrusion is a continuous moulding process fabricating products of uniformsection such as I Beams, Channels, flat Bars, Rods,Hollow Sections, etc. Msing glass fibre, resin, fillet peroxide and a release agent. The glass reinforcement is drawn into a resin impregnation zone where the Mass substrate is thoroughly impregnated with the main mixture. The wet fibrous materiss will be pulled through a preformer into a heated die. The shape of the end product is determined by the configuration of the die and the resin is then polymerised. This continuous and uniform method ensures consistency throughout the entire product length, therefore eliminating the possibility of weak spots.

FRP Pultrusion Process - Continuous Pultrusion

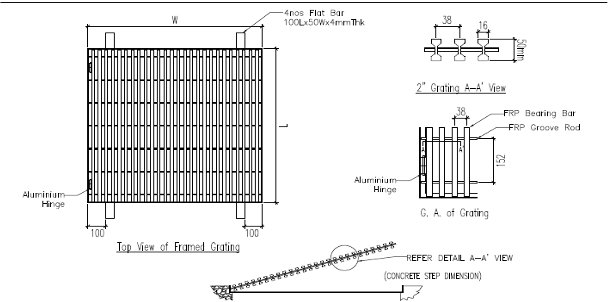

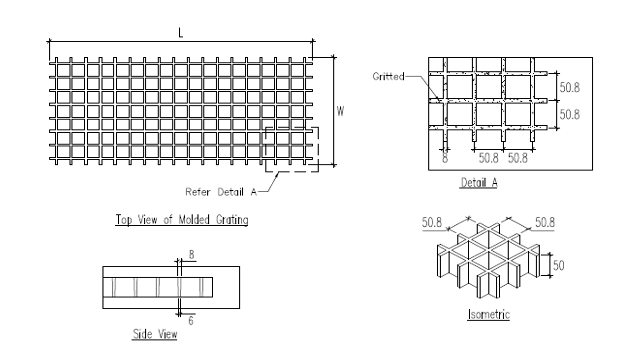

INTECH FRP PULTRUDED & MOLDED GRATING

Applications

Download Product Catalogue

Explore our comprehensive product offerings! Download our latest catalogue now to discover the full range of solutions tailored to meet your needs