Custom Solutions

Custom Solutions

FRP (Fiberglass Reinforced Plastic) is produced from a combination of fiberglass reinforcements and thermosetting resins. Since its introduction, this special millennium product has gained wide acceptance for its superior benefits and is presently used all over the world.

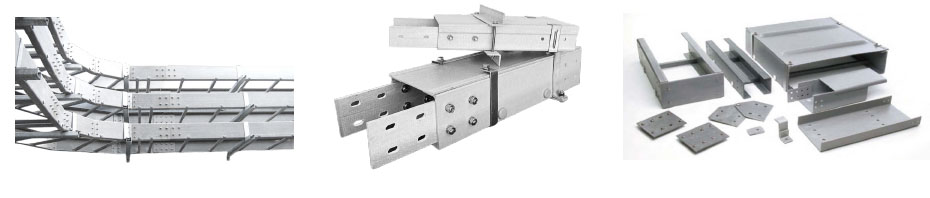

INTEC Cable Support System

INTECH Cable Support System (Tray & Ladder) are designed to comply internationally ecognized NEMA & IEC standards. Various range of material are built to be anti-corrosive , fire retardant and non conductive. servicing the growing market segment within oil & gas, power generation, water treatment and renewable energy industry, where corrosion is a real-life encountered issue.

INTECH cable support system offers range of resins to match our clients requirement.

Benefits of Pultrusion FRP Products

Corrosion Resistant

No rusting, peeling or flaking even under the most aggressive conditions in any part of the world.

High Impact Resistant & Elastic

Choose a pre-built header or create a custom layout that perfectly suits your needs.

Lightweight and Durable

Allows easy handling and cutting and reduce size of platform structure.

Superior UV Protection

Integral UV protection system gives long-term shield against the damaging effects of UV rays.

Cost Effective

Extremely long life and completely maintenance-free

Non-Conductive & Non-Interfering

Doesn't conduct heat like metal and remains unaffected by heat expansion.

High Strength and Stiffness

High glass content and continuous reinforcement, pultruded FRP products that give extremely high strength and stiffness

Fire Retardant

Complies to ASTM-E84 and BS 476 standards.

High Impact Resistant & Elastic

Returns to original position without any permanent deflection or distortion within allowable loads.

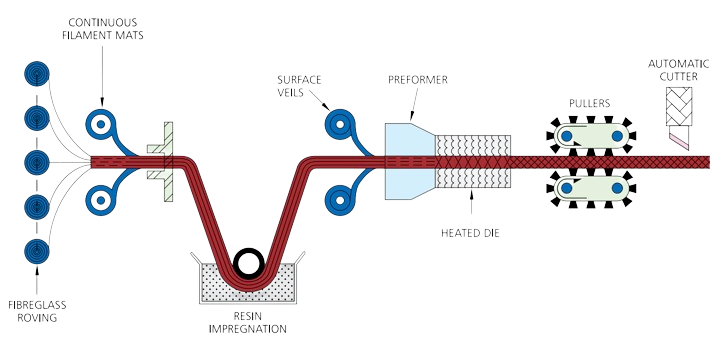

What is Pultrusion Process

Pultrusion is a continuous moulding process fabricating products of uniformsection such as I Beams, Channels, flat Bars, Rods,Hollow Sections, etc. Msing glass fibre, resin, fillet peroxide and a release agent. The glass reinforcement is drawn into a resin impregnation zone where the Mass substrate is thoroughly impregnated with the main mixture. The wet fibrous materiss will be pulled through a preformer into a heated die. The shape of the end product is determined by the configuration of the die and the resin is then polymerised. This continuous and uniform method ensures consistency throughout the entire product length, therefore eliminating the possibility of weak spots.

FRP Pultrusion Process

The latest design trends meet hand-crafted templates in Hub Collection. Use pre-built sections to speed up your design process.

Applications

Intech FRP Resin Guideline

Isophathalic (ISO) Resin is the most commonly used resin that provides good corrosion and ultraviolet light resistance for various application.

VE resin is formulated for reliable performance in the harshest chemical environment, providing outstanding resistance towards wide range of highly corrosive applications ranging from causting to strong acidic.

IFR resin is designed for indusrial and chemical processing application where fire retardancy is required.

Intech ISO FR Resin formulation has been derived to meet fire retardancy and low smoke development index, classified with class A standard in accordance to ASTM E84.

Download Product Catalogue

Explore our comprehensive product offerings! Download our latest catalogue now to discover the full range of solutions tailored to meet your needs