Structural Profiles

Structural Profiles

INTECH FRP structural profiles are developed and marketed to both local and oversee regional countries by Intralink Techno Sdn Bhd since 1999. Various types of FRP structural profiles ere available for numerous tapplicetdns such es coding tower structure, off-shore construction, tunnel and subway, marine Industry, oil and gee industry, building end ennstniction industry, process end demicd glad, water or waste treatment plant and others. These FRP structural profiles Include floor decking, guentreil hollow section, channel, angle end bar stock. The FRP products are able to comply with highest requirements of oil and gas Industry to provide uNmate fire redrdency and low smoke generation, end excellent features like corrosion resistant, thermal and on Insulation, lightweight and high strength and others. With the availability of product ranges and proven quality, nk -rechno son Elnd is capable of offering most of the solution to fulfill the customer requirement and satisfaction.

Features / Uniqueness

Corrosion Resistant

No rusting, peeling or flaking even under the most aggressive conditions in any part of the world.

Lightweight high strength

Choose a pre-built header or create a custom layout that perfectly suits your needs.

Superior UV protection

Allows easy handling and cutting and reduce size of platform structure.

Field drillable

Integral UV protection system gives long-term shield against the damaging effects of UV rays.

Thermal insulation

Extremely long life and completely maintenance-free

Easy to install and handle

Doesn't conduct heat like metal and remains unaffected by heat expansion.

Electrical insulation

High glass content and continuous reinforcement, pultruded FRP products that give extremely high strength and stiffness

Cost effective

Complies to ASTM-E84 and BS 476 standards.

Durability

Returns to original position without any permanent deflection or distortion within allowable loads.

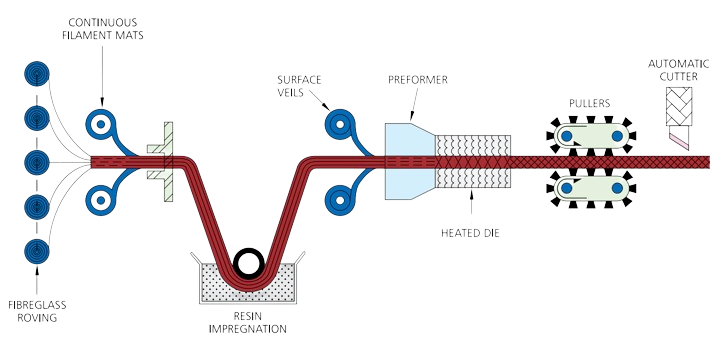

What is Pultrusion Process

Pultrusion is a continuous moulding process fabricating products of uniformsection such as I Beams, Channels, flat Bars, Rods,Hollow Sections, etc. Msing glass fibre, resin, fillet peroxide and a release agent. The glass reinforcement is drawn into a resin impregnation zone where the Mass substrate is thoroughly impregnated with the main mixture. The wet fibrous materiss will be pulled through a preformer into a heated die. The shape of the end product is determined by the configuration of the die and the resin is then polymerised. This continuous and uniform method ensures consistency throughout the entire product length, therefore eliminating the possibility of weak spots.

FRP Pultrusion Process

The latest design trends meet hand-crafted templates in Hub Collection. Use pre-built sections to speed up your design process.

Applications

Download Product Catalogue

Explore our comprehensive product offerings! Download our latest catalogue now to discover the full range of solutions tailored to meet your needs